materials we commonly work with

-

316 stainless steel

As marine specialists we machine 316 stainless every day and we frequently billet machine stainless steel to create organic forms like the bow fairlead above, which weighed nearly 17Kg Nearly all our stainless work is mirror polished to exceptional standards.

-

Titanium

Light and strong makes titanium a great choice for weight sensitive projects. We have extensive tooling to allow us to machine this metal efficiently. We work in titanium most weeks. It polishes well but we like the more technical finish we used our own take on the humble bottle opener.

-

Aluminium

Light and fast to machine, aluminium is a great choice where strength is not critical. We work hard on achieving a great finish during and after machining, as we anodise most parts for durability and visual appeal. The image is of a small part that holds a proximity sensor.

-

Tool Steel

Tool steels encompass a wide variety of carbon and alloy steels with different material properties and are often heat treated to improve their hardness.

We machine some intricate and highly toleranced parts for a very prestigious client. A great deal of our work is covered by NDA’s and we always respect client confidentiality, so unfortunately, we can’t share any images of this one!

-

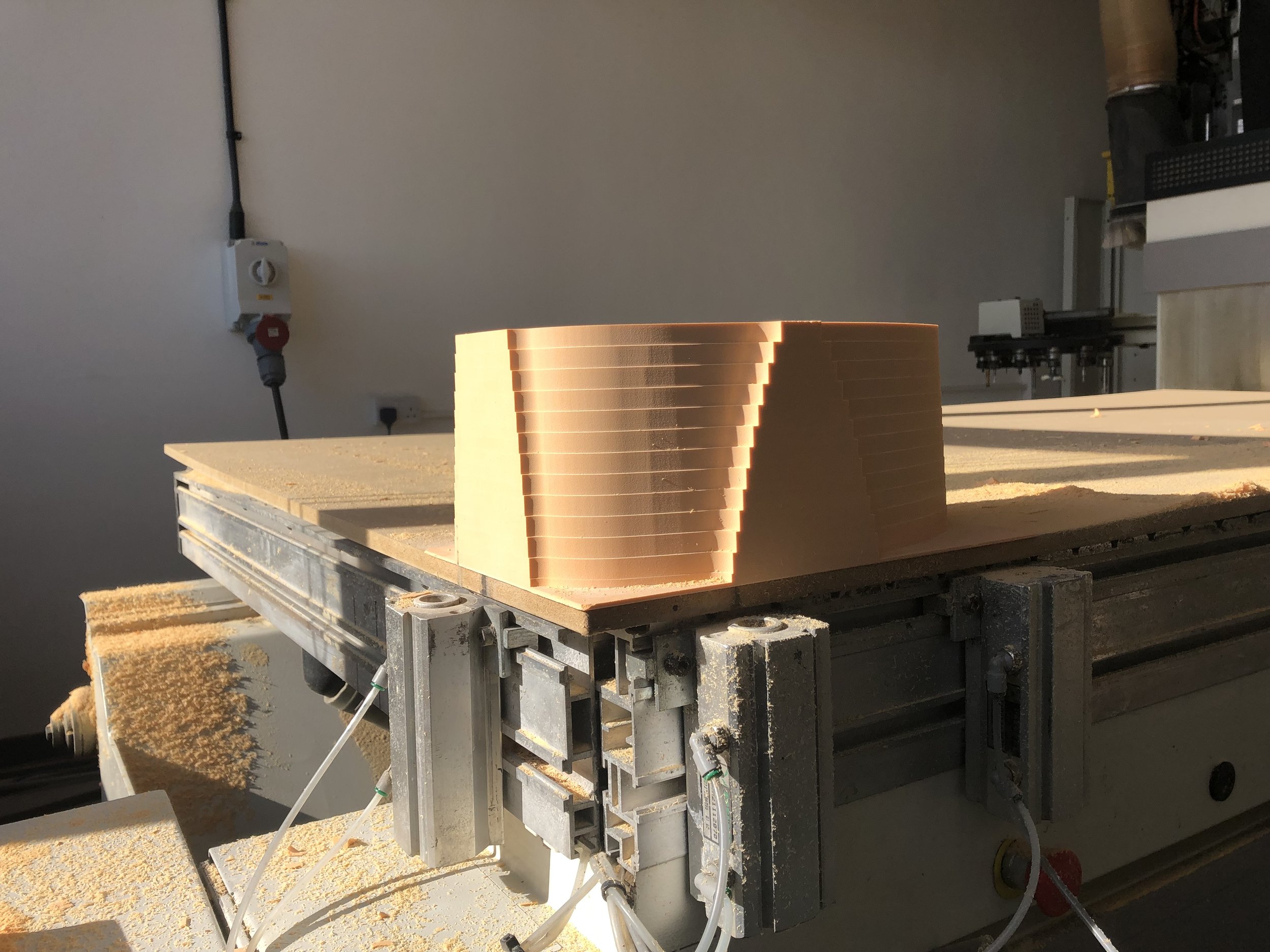

Tooling Board

Tooling Board is used to make patterns, plugs and direct moulds. We use both PU and epoxy boards of different densities to suit the requirement. We machine this material on our routing centre or one of our mills if appropriate.

This image shows intiital roughing cuts on a part that went on to become a mould for a mast partner collar.

-

Carbon Fibre

Light, strong, does not corrode and looks great! All qualities that make carbon fibre an essential part of the Carbinium stable.

The image here is a detail shot of a part straight out of the mould - made by us of course! We would love to show you more of this component but we have yet to launch the product.

-

Brass

Looks gorgeous and can be polished to a very high standard, but it is soft and marks easily. We typically machine brass for interior projects where we are working with a specialist joinery business. This 5 axis machined part forms part of the arm of a series of custom chairs our client was making.

-

Acetal

Acetal, Delrin and other engineering plastics are a necessary part of many designs. All our metals are fully recycled and we minimise our plastic waste as much as possible. The part above was part of a retrofit solution for a client who needed a smooth rope lead.

-

Timber and sheet materials

We machine timber, plywood and other sheet materials on our 3 axis routing centre. The beautiful parts here are machined from solid Sipo and went on to become cabin doors with a hidden handle.